Need to measure roughness, hardness,

gloss or thickness?

Our product range covers everything from entry-level models to advanced solutions capable of handling complex tasks with features for data sharing and comprehensive documentation.

THICKNESS GAUGES

Coating thickness gauges are used for precise measurement of coating and surface layer thickness, essential for quality control and documentation in various industries.

ULTRASONIC GAUGES

Ultrasonic thickness gauges enable fast and accurate measurement of material thickness without dama-ging the object, making them ideal for inspection and maintenance.

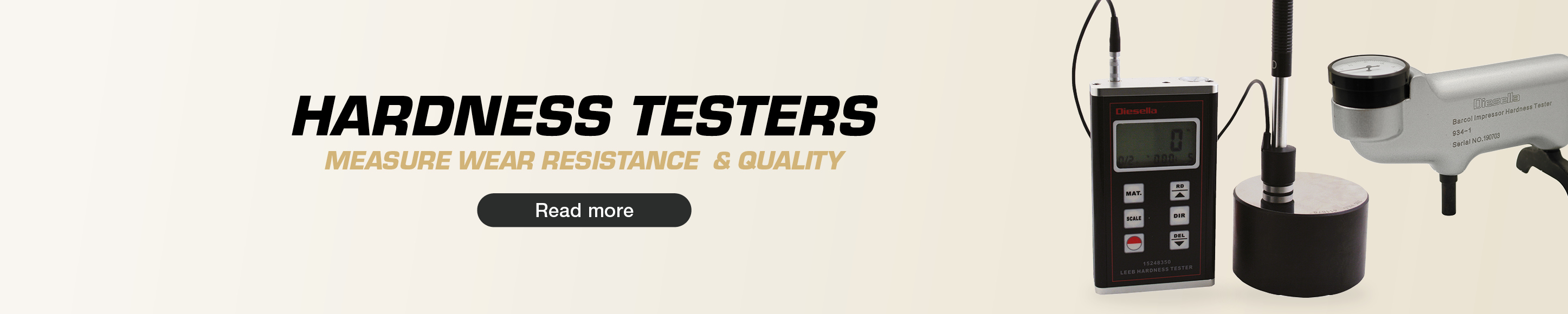

HARDNESS TESTERS

Hardness testers measure a material’s resistance to pressure or impact and are used to assess wear resistance, durability, and overall quality in many technical applications.

Discover: X300 PRO

Precise and flexible coating thickness gauge with external ruby probe. Get accurate measurements—even in hard-to-reach areas.

This advanced coating thickness gauge is designed for both magnetic (Fe) and non-magnetic (NFe) metals, delivering reliable results—ideal for paint, galvanizing, zinc, plastic coatings, aluminum, copper, and more.

Key features:

✅ Durable external ruby probe: Perfect for measuring in tight or confined spaces

✅ Automatic substrate detection: Smart technology identifies the base material

✅ High accuracy: ±2% + 1µm for measurements below 2000µm

✅ Wireless app connectivity: Effortless data transfer and analysis

✅ All-in-one kit: Includes test plates, calibration foil, user manual,

2x AAA-batteries and a practical storage case.

Ideal for both professionals and DIY enthusiasts who demand precise measurement results.

Ultrasonic thickness gauge

Precision for the most demanding tasks

When only the highest precision is good enough! The DC-6000 is an advanced ultrasonic thickness gauge, perfect for ultra-trin materials and applications requiring high resolution. With A/B-scan capabilities and both T-E and E-E measurement modes, you get accurate and reliable thickness analysis across a wide range of materials from metals and plastics to ceramics and glass.

✅ High precision measurements: Ideal for inspection and maintenance in the oil, gas, wind, construction, and manufacturing industries

✅ Ultrasonic technology: Easily measures the thickness of a wide variety of materials

✅ A/B-scan function: For detailed visualization and fault detection

✅ Operating temperature: -20 °C to +50 °C – suitable for tough environments

✅ Large digital color display (320x240 mm): Provides a clear and intuitive overview

✅ Optional speciality probes: For customized measurement needs (sold separately)

What's in the box:

📦 DC-6000 unit with large color TFT-display

📦 Standard probe (S1507)

📦 Built-in calibration block

📦 USB-cable, user manual & calibration certificate

📦 75 ml gel

📦 Storage box

Precise hardness tester

Measures in 5 hardness scales

Get fast and accurate measurements of metal hardness in Rockwell (HRB/HRC), Vickers (HV), Brinell (HB), Leeb (HL) and Shore (HS) – ideal for production lines, material inspection and failure analysis. Perfect for testing molds, bearings, pressure vessels, steam generators, heavy workpieces and installed machine parts.

Key features:

✅ Test at any angle – even upside down!

✅ Direct reading in 5 hardness scales – HRB, HRC, HV, HB, HS, HL

✅ Measures 9 differnt metals, incl. steel, tool steel, cast aluminum, brass and copper

✅ High precision – minimum requirements: 3 mm material thickness, 0,8 mm hardened layer

✅ Large memory – save up to 50 measurements

✅ Easy operation – manual or automatic shut-off

✅ Low battery-indicator – ensures stable performance

Efficient, accurate and easy to operate – a must-have tool for industrial quality control and inspection.

Litesurf: Fast and easy documentation

Transfer data in seconds

Litesurf stands out with its small, lightweight and compact design combined with maximum flexibility. Perfect for projects where efficient data documentation is essential.

Key features:

✅ Wireless Bluetooth connection: Ultra-fast data transfer to your computer or tablet

✅ User-friendly and versatile: Compact design fits any work environment

✅ View and document measurements in seconds: Boost your project efficiency

💡 Make your data documentation easier, faster and

more accurate with Litesurf

Gloss meters

Gloss meters are used to measure the surface's ability to reflect light, indicating its gloss level. This tool is important in quality control, especially in painting, coating, plastic and other surface treatments where a consistent finish is crucial. Gloss meters are also used to evaluate wear or aging of surfaces over time.